Hot Keywords: Industrial dehumidifier | Special dehumidifier | High temperature Dehumidifier | Constant temperature and humidity machine

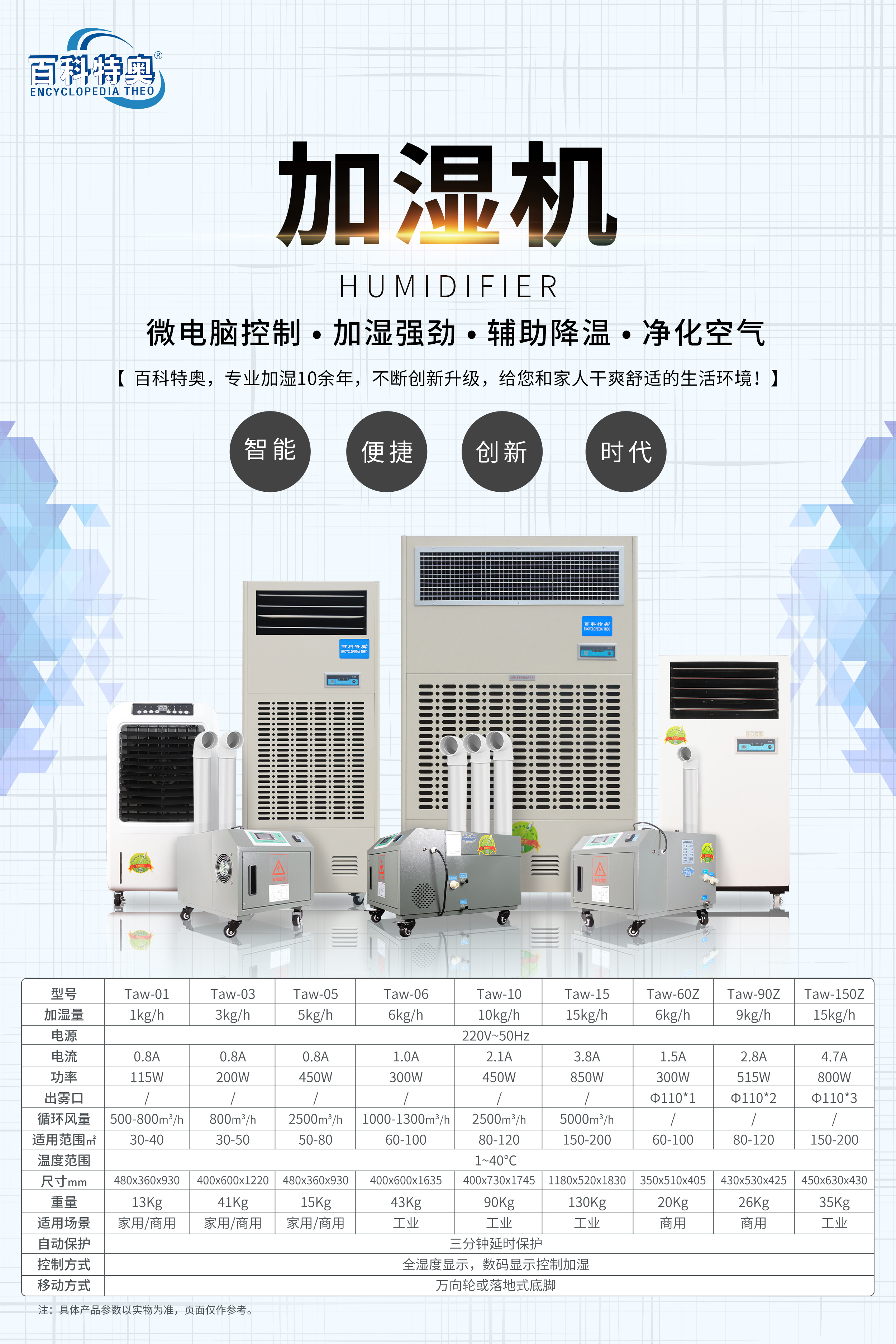

Baike Teao Humidifier Series

Release time:

Aug 04,2023

Source:

Wet film humidifier

Using biological wet film technology for humidification, it utilizes the evaporation of water, continuously delivering water to the upper part of the wet film through a water pump and distributor. Under the action of gravity, water returns to the main water tank through the wet film, forming a cycle. When dry air passes through the wet film, the air fully contacts the wet film, and the moisture in the air vaporizes the water, increasing humidity to achieve the purpose of humidification.

Powerful humidification, no white mist phenomenon; uses imported plant wet film to purify air; features fully automatic control with digital computer, LCD backlight display; humidity can be set from 1-99%, with two-speed wind adjustment; large and uniform humidification range; uses Panasonic solenoid valve for independent control, safe and reliable; the device's water tank uses dual float detection for precise stability; electronic detection, leak protection function, and alarm function for faults; user-friendly design with cumulative working time and manual mode for automatic water replacement; stainless steel water tank, mold-proof, antibacterial, and durable; has ventilation mode to circulate indoor air.

Ultrasonic humidifier

Uses electronic ultrasonic oscillation (oscillation frequency of 1.7MHz, beyond the range of human hearing, harmless to humans and animals), through the high-frequency resonance of the atomization plate, water is thrown off the surface to create a naturally floating mist without the need for heating or chemicals, producing 1-10μm water particles that float in the air, achieving air moistening effects. At the same time, suitable relative humidity plays a decisive role in improving product quality, reducing waste rates, preventing static electricity, eliminating dust, purifying air, and improving the environment.

-

Combines wall-mounted and mobile design, allowing for both mobility and wall suspension.

-

Humidity control system, using internationally top imported probes, with control accuracy error within ±5%.

-

Internally uses an integrated atomization module, with replaceable chips for easy maintenance.

-

The mist particle diameter output by the whole machine is only 1-10μm, with a maximum relative humidity of over 99%.

-

Equipped with standard water inlet, waterproof switch, overflow outlet, etc., where the water inlet can be optionally configured with soft water to meet the requirements of no calcification, no white powder, and no pollution for different water qualities.

-

The mist outlet is detachable and very easy to clean.

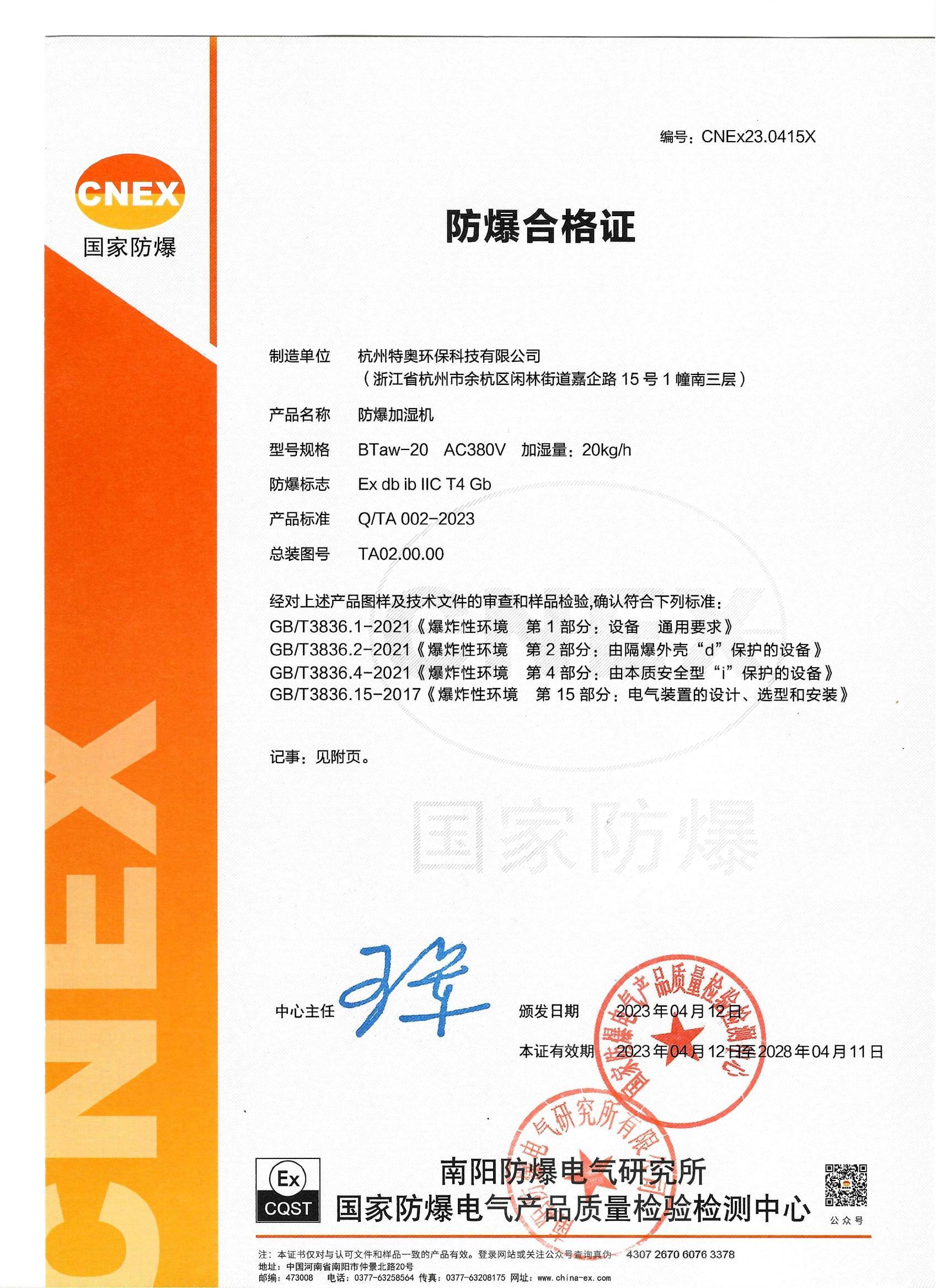

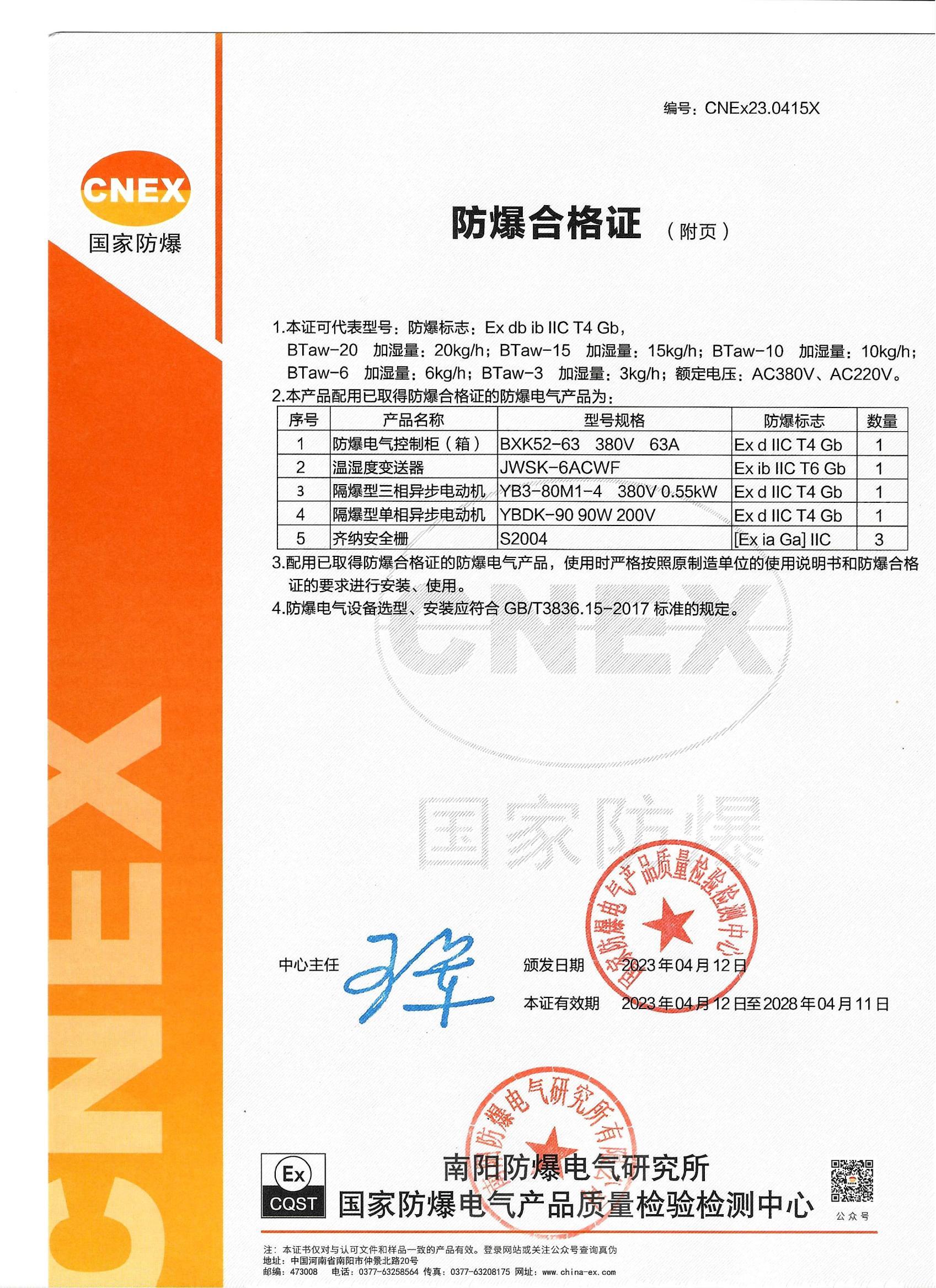

Explosion-proof humidifier

The machine is processed through special explosion-proof technology and can be widely used in explosion-proof zones 1 and 2, covering various industries such as national defense, scientific research, petroleum, chemical, pharmaceutical, manufacturing, and biopharmaceuticals. It is designed for special humidification equipment in places where there may be II A, II B level, T1~T4 group combustible gases, vapors, and air mixtures that are prone to explosion, with an explosion-proof mark of ExdbibⅡCT4 Gb.

Implementation standards

-

GB/T3836.1-2021 Electrical equipment for explosive gas atmospheres Part 1: General requirements for equipment

-

GB/T3836.2-2021 Electrical equipment for explosive gas atmospheres Part 2: Equipment protected by flameproof enclosures "d"

-

GB/T3836.4-2021 Electrical equipment for explosive gas atmospheres Part 4: Equipment protected by intrinsic safety "i"

-

GB/T3836.9-2021 Electrical equipment for explosive gas atmospheres Part 9: Encapsulation "m"

-

GB/T3836.15-2017 Electrical equipment for explosive gas atmospheres Part 15: Design, selection, and installation of electrical devices

-

GB/T23332-2009 Humidifiers

-

GB4208-2008 Enclosure protection level (IP code)

Related News

Why Commercial Dehumidifiers Are Essential for Modern Businesses

Discover why businesses rely on commercial dehumidifiers to protect products, reduce costs, and improve air quality. Learn more from Teao.